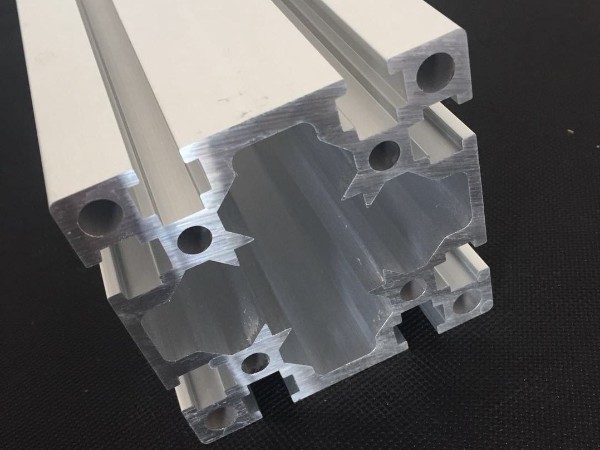

Treatment and Inspection of Castings

Release time:

2023-12-28

Metal casting types modeling methods are customarily divided:

Ordinary sand casting, including wet sand, dry sand and chemical hardening sand 3 categories.

② special casting, according to the modeling materials can be divided into natural mineral sand as the main modeling materials of special casting (such as investment casting, mud casting, casting workshop shell casting, negative pressure casting, solid casting, ceramic casting, etc.) and metal as the main mold material of special casting (such as metal casting, pressure casting, continuous casting, low pressure casting, centrifugal casting, etc.).

Metal casting processes typically include:

① mold (liquid metal into a solid casting container) preparation, mold according to the materials used can be divided into sand, metal, ceramic, mud, graphite, etc., according to the number of use can be divided into one-time, semi-permanent and permanent type, the advantages and disadvantages of mold preparation is the main factor affecting the quality of castings;

The melting and pouring of cast metals, cast metals (casting alloys) are mainly cast iron, cast steel and cast non-ferrous alloys;

③ Casting treatment and inspection, casting treatment includes removal of foreign matter on the surface of the core and casting, removal of sprue, shovel sanding, spines and lances, as well as heat treatment, shaping, anti-rust treatment and rough machining.